|

|

Asphalt Materials Laboratory

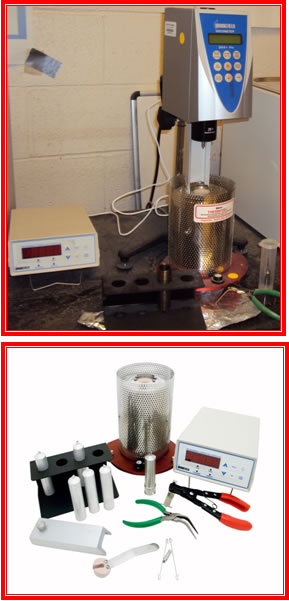

1.BENDING BEAM RHEOMETER

The Bending Beam Rheometer (BBR) was develpped by Strategic Highway Research Program (SHRP) to performs flexural tests on conventional and modified asphalt binder based on ASTM D6648-01 and AASHTO T313-02. A constant force is applied to a specimen in a fluid bath in order to obtain creep deformation at low temperatures. ATS BBR system consists of a fluid bath base unit, a three-point bending test apparatus which is easily removed from the base unit for specimen loading and unloading, an external cooling unit with temperature controller, and a calibration hardware kit with carrying case. Further, the BBR has been redesigned according to the latest revisions of ASTM and AASHTO specifications.

2.ROLLING THIN FLIM OVEN (RTFO)

The rolling thin film oven test simulates binder aging (hardening) during production and construction of asphalt concrete mixtures. During the test it continually exposes fresh asphalt binder to heat and air flow during rolling and takes only 75 minutes to perform test compared to thin film oven, which takes five hours. The binders aged under this test are then tested for fatigue and rut resistance using DSR equipment.

In this study the James Cox and Sons Rolling Thin Film Oven is requested which are designed and manufactured in the USA, with a five-year manufacturer's warranty. It has the following features.

- Temperatures are controlled using a precision resistance temperature detector (RTD) sensor.

- Unique suppression feature built into the controller for very fast response time with minimal overshoot.

- Digital flowmeter accurate to ±1.0% at a rate of 4,000mL per minute.

- Solid-state digital temperature controller with built-in over-temperature protection (±1°F at 325°F).

- Baked enameled steel exterior, and double-wall construction for added safety and energy efficiency.

- The circular test rack holds eight serial-numbered RTFO Bottles (included) and rotates at 15rpm.

3.PRESSURE AGING VESSEL (PAV)

The Pressure Aging Vessel was developed by SHARP to simulate the long-term aging of asphalt binder due to oxidation. Tests can be conducted according to AASHTO R28, ASTM D6521 and EN 14769. ATS PAV is requested for the proposed equipment proposal. The equipment has the following.

- Use heated pressurized air to simulate long-term oxidative aging.

- Consist of an ASME-Code and CE certified stainless steel pressure vessel, stainless steel cabinet with encased band heaters, and integral pressure measurement control.

- A platinum RTD device to insure accurate temperature resolution.

- A pressure relief valve and high-temperature thermal shut-down are included as safety features.

- A USB port located on the front of the unit allows the user to easily store test data and upgrade software.

- The system now includes remote operation capabilities, and allows the user to completely control the PAV using an app compatible with most smart phones and tablets.

- Touch-Screen Controller with front panel user interface for complete control and monitoring of all test.

- The system has an operating pressure range of 2.1 ±0.1mPa, and temperature range of 80°—115°C.

4.VACUUM DEGASSING OVEN (VDO)

The Vacuum Degassing Oven is used to precisely and accurately degas pressure-aged binder samples to meet AASHTO R28-06 and ASTM D6521-05 standards. This is used in conjunction with PAV. ATS VDO uses an electrically powered vacuum system to quickly evacuate the chamber to 15kPa. The chamber has a capacity of four samples.

5.LABORATORY OVEN

Laboratory oven is specially designed to conduct Superpave asphalt mix design operations in the IML laboratory.

6.HOT MIX ASPHALT (HMA) MIXTURE

Pine Superpave Gyratory Compactor (SGC)

- SGC is a key component of the Superpave mixture design whose primary function is to fabricate test specimens by simulating the effect of traffic on an asphalt pavement. The specimens fabricated with the gyratory compactor are used to determine the volumetric properties (air voids, voids in the mineral aggregate, and voids filled with asphalt) of HMA mixtures.

- SGC consists of a rigid reaction frame, loading system, and specimen height measurement and recordation. There are three parameters that control the compaction effort. These include constant vertical pressure, angle of gyration and number of gyration. SGC compacts asphalt mixture specimens at a constant vertical pressure of 600 kPa. The mixture is compacted by a gyratory kneading action using a compaction angle of 1.25 degrees and operating at 30 rpm. The number of gyrations is varied to simulate traffic level. SGC can compact samples 150 mm (6-inch) or 100 mm (4-inch) diameter.

7.MARSHALL COMPACTOR

For 4" diameter specimens. 115V 60Hz. The Automatic Marshall Compaction Machine is designed to provide a stable and rigid mechanism for producing 4" or 6" diameter asphalt pills used in Marshall tests. The heavy-duty design stands up well to the constant jarring caused by the compaction process. The Compaction Machine features a rotating mold mechanism and a hammer with a beveled foot, which together produce a kneading action when producing test pills. The machine's automatic counter allows the operator to preset the number of blows wanted and will turn off the machine when completed. A cam-action lever operates the integral mold holder to facilitate insertion and removal of the stability mold.

8.STANDARD BENCH HMA MIXTURE

Industrial grade, Laboratory Mixers have planetary action for thorough mixing, blending and aerating of materials. Direct gear drives and heavy-duty motors assure constant mixing speeds under load. Locking hand-lever raises and lowers bowls. Mixers, except MA-52, adjust for proper clearance between beater and bowl. Mixers are supplied with stainless steel bowls, wire whips and flat aluminum beaters. Models noted include additional beater or other modifications to meet certain ASTM and AASHTO specifications. Add "F" suffix to model number for units that operate on 230V/50Hz power supply.

- 15 quart (14.2 liter) bowl capacity.

- Space-saving, bench-top design.

- Unique 2-piece swing open safety guards.

- Continuously variable transmission delivers more power to beater head shaft and allows the user to change speeds while the mixer is running.

9.QUARTERMASTER ™ ASPHALT DIVIDER

Designed to handle the large samples required in Superpave ® specifications, Gilson’s patented Quartermaster ™ safely and accurately divides any hot-mix asphalt sample for quality control analysis. Field samples of 120lb (55kg) or more are quickly reduced, ensuring representative samples for consistent laboratory results. Large hopper reduces handling of hot material during preparation of laboratory samples. Quartermaster ™ has a proven history of significantly reducing bias in sample reduction. Designed to handle the large samples required in Superpave ® specifications, Gilson’s patented Quartermaster ™ safely and accurately divides any hot-mix asphalt sample for quality control analysis. Field samples of 120lb (55kg) or more are quickly reduced, ensuring representative samples for consistent laboratory results. Large hopper reduces handling of hot material during preparation of laboratory samples. Quartermaster ™ has a proven history of significantly reducing bias in sample reduction.

In operation, a hot-mix sample is loaded evenly into the hopper. When the handle is released, the sample falls through the divider which is designed to distribute equally into four separate containers. Only occasional clean up is required to prevent buildup on exposed surfaces.

10.BULK SPECIFIC GRAVITY OF HMA MIXTURE

Specific Gravity Bench is designed for convenient weigh-below use when determining specific gravity of aggregates, hardened concrete, bituminous mixtures, refractory brick, and similar materials where weighings must be made with samples suspended in water. Bench top is a 31x25in (787x635mm) platform with three 2in (51mm) dia. holes for suspension of samples and thermometer. Lower tank shelf has two locations to fit tanks of 18in or 24in (457 or 610mm) internal depth. Bench is sturdy, painted-steel and requires assembly. Specific Gravity Bench is designed for convenient weigh-below use when determining specific gravity of aggregates, hardened concrete, bituminous mixtures, refractory brick, and similar materials where weighings must be made with samples suspended in water. Bench top is a 31x25in (787x635mm) platform with three 2in (51mm) dia. holes for suspension of samples and thermometer. Lower tank shelf has two locations to fit tanks of 18in or 24in (457 or 610mm) internal depth. Bench is sturdy, painted-steel and requires assembly.

- Heavy-duty polyethylene water tanks (44 gallons water capacity)

- Wire Mesh Buckets

- Specific Gravity Bench

- Heater/Circulator

- Thermometer, ASTM 17C

- Volumeter

- Scale, 20kg x 0.1g

11.MASONRY SAW WITH DIAMOND BLADE

Masonry saws include a lightweight 2hp Portable Model and a 5hp Heavy-Duty Model for high production applications. The Portable Saw accommodates 14in (356mm) diameter blades for up to 5in (127mm) cut depth. Heavy Duty accomodates 20in (508mm) blades for up to 8in (203mm) cut depth. Both include double V-belt drives, high-torque motors, and submersible water pumps to permit wet cutting. Sealed lifetime-lubricated cutting head pivot point bearings are seated in a machined saddle to give precise alignment and long blade life. Blade guards stay parallel to the wheel-mounted rubber-topped cast aluminum cutting cart for safety, visibility, and convenience. Heavy-duty blade shafts are mounted on quality ball bearings. Masonry saws include a lightweight 2hp Portable Model and a 5hp Heavy-Duty Model for high production applications. The Portable Saw accommodates 14in (356mm) diameter blades for up to 5in (127mm) cut depth. Heavy Duty accomodates 20in (508mm) blades for up to 8in (203mm) cut depth. Both include double V-belt drives, high-torque motors, and submersible water pumps to permit wet cutting. Sealed lifetime-lubricated cutting head pivot point bearings are seated in a machined saddle to give precise alignment and long blade life. Blade guards stay parallel to the wheel-mounted rubber-topped cast aluminum cutting cart for safety, visibility, and convenience. Heavy-duty blade shafts are mounted on quality ball bearings.

12.RESIISTANCE OF COMPACTED BITUMINOUS MIXTURE TO MOISTURE INDUCED DAMAGE

13.DESPATCH FORCED AIR BENCH OVENS

For faster processing, testing, preheating, sterilizing, drying, aging, curing and other production applications. Despatch LAC ovens have microprocessor-based control system with single set-point operation, timer function and up to 48 steps of ramp/soak programming as well as manual reset high-limit protection and solid-state relay switching. Horizontal air flow with high fan volume of forced recirculated air through perforated stainless steel walls for uniform heating. Welded double-wall construction, 3" Fiberglass insulation, rapid-response heater, baked enamel finish and stainless steel interior. For faster processing, testing, preheating, sterilizing, drying, aging, curing and other production applications. Despatch LAC ovens have microprocessor-based control system with single set-point operation, timer function and up to 48 steps of ramp/soak programming as well as manual reset high-limit protection and solid-state relay switching. Horizontal air flow with high fan volume of forced recirculated air through perforated stainless steel walls for uniform heating. Welded double-wall construction, 3" Fiberglass insulation, rapid-response heater, baked enamel finish and stainless steel interior.

Despatch Model No.: LAC2-12, Chamber Size W x D x H in. (cm): 24 x 24 x 36" (61 x 61 x 90cm), Capacity: 12 cu. ft. (340L), Overall Size W x D x H in (cm): 36 x 33 x 54" (91 x 84 x 137cm), Operating Range w/20°C Ambient: 50-260°C (122-500°F), Exhaust Diameter: 2-2-1/2", no cord and plug, 50/60Hz, 240V, 18.4 amps, 3.6 KW heater

14.ASPHALT BINDER

Brookfield Rotational Viscometer

Rotational Viscometers and Rheometers provide rapid, reproducible high-temperature viscosity measurements that correlate closely with the time-consuming AASHTO T 201 glass capillary method. Asphalt binder products are tested for pumping characteristics and temperature/viscosity charts can be developed to estimate mixing and compaction temperatures in hot-mix design. Torque required to rotate a spindle immersed in the specimen is measured and yields a proportional dynamic viscosity value. Rotational Viscometers and Rheometers provide rapid, reproducible high-temperature viscosity measurements that correlate closely with the time-consuming AASHTO T 201 glass capillary method. Asphalt binder products are tested for pumping characteristics and temperature/viscosity charts can be developed to estimate mixing and compaction temperatures in hot-mix design. Torque required to rotate a spindle immersed in the specimen is measured and yields a proportional dynamic viscosity value.

Brookfield systems to measure viscosity between 100cP and 40 million cP. Both are accurate to ±1% and reproducible to ±0.2%. The units can measure at sample temperatures from 9°-60°C (40&de-00°F) and are compatible with a variety of spindles. Viscosity in cP or mPa/s, temperature in °C/°F, percent torque, shear rate, shear stress in dynes/cm2, and spindle number are displayed continuously during operation. An easy to use key pad allows stand-alone programming of test parameters, and built-in RTD probes accurately monitor sample temperature. Parallel printer ports, serial RS-232 interface and analog voltage outputs are also provided. Calibration torque is 7,187 dyne cms, full-scale for both units.

LP-2R RVDV-II+ Pro Viscometer has 54 selectable speed options from 0.01-200 rpm and a two-line LCD display. Up to four selectable test programs can be programmed to memory.

Applicable Tests : AASHTO TP 48, ASTM D 4402, SHRP 1006

15.BOLIN'S DYNAMIC SHEAR RHEOMETER

16.UNIVERSAL PENETROMETER

The Universal Penetrometer tests a wide variety of materials by penetration of weighted needles or cones. Main applications are for bituminous materials, but waxes, greases, foods, and pharmaceuticals are among other products tested. Penetration is read from a 5in (127mm) diameter indicator dial of 400 divisions, each representing 0.1mm of penetration. The Universal Penetrometer tests a wide variety of materials by penetration of weighted needles or cones. Main applications are for bituminous materials, but waxes, greases, foods, and pharmaceuticals are among other products tested. Penetration is read from a 5in (127mm) diameter indicator dial of 400 divisions, each representing 0.1mm of penetration.

Manual Penetrometer is ruggedly constructed for accurate, sensitive measurements. The aluminum base has a machined, grooved table with leveling screws and rubber inserts to protect tips of needles and cones. Two stainless steel rods act as support guides for a cast aluminum head with coarse/fine adjustments and a calibrated friction-free plunger mechanism. Indicator dial has instant zero reset. Any needle or cone with standard 1/8in (3mm) diameter stem may be mounted to the 47.5g plunger assembly. A standard 2.5g ASTM D 5 Needle (HMA-180) and two additional loading Weights (50g and 100g) are included.

Applicable Tests: AASHTO T49, ASTM D 1168, ASTM D 1191, ASTM D 1321, ASTM D 1403, ASTM D 1831, ASTM D 1855, ASTM D 217, ASTM D 2884, ASTM D 2994, ASTM D 3582, ASTM D 5, ASTM D 937

17.SOFTENING POINT TESTER

Ring and Ball Apparatus is used for determining the softening point of asphalt, coal tar pitch, and other viscoelastic bitumens in the range of 30°-157°C (86°-315°F). Steel balls are placed on top of bitumen specimen disks in test rings in a bath. Temperature of the bath is increased gradually until the specimens soften and fall under the ball weight to the shelf 1in

(25.4mm) below. The Softening Point Apparatus provides for simultaneous testing of two specimens as suggested in standard test procedures. The Apparatus includes two square-shouldered brass test rings, two 3/8in (9.5mm) steel balls, two brass ballcentering guide rings, an 800ml heat-resistant beaker (bath), and a brass ring holder suspension assembly with cover and shelf to fit beaker as per specs. If not already available in the lab, a Tirrill Burner, ASTM Softening Point Thermometers, and a Beaker Stand Assembly should also be purchased. The Beaker Stand Assembly includes Ring and Ball Apparatus is used for determining the softening point of asphalt, coal tar pitch, and other viscoelastic bitumens in the range of 30°-157°C (86°-315°F). Steel balls are placed on top of bitumen specimen disks in test rings in a bath. Temperature of the bath is increased gradually until the specimens soften and fall under the ball weight to the shelf 1in

(25.4mm) below. The Softening Point Apparatus provides for simultaneous testing of two specimens as suggested in standard test procedures. The Apparatus includes two square-shouldered brass test rings, two 3/8in (9.5mm) steel balls, two brass ballcentering guide rings, an 800ml heat-resistant beaker (bath), and a brass ring holder suspension assembly with cover and shelf to fit beaker as per specs. If not already available in the lab, a Tirrill Burner, ASTM Softening Point Thermometers, and a Beaker Stand Assembly should also be purchased. The Beaker Stand Assembly includes

metal support stand, ring clamp, wire gauze, and thermometer clamp.

Applicable Tests: AASHTO T53, ASTM D 36

18.FLASH POINT TESTER

The Cleveland open cup method is used to measure the flash and fire points of all petroleum products except fuel oils and those materials which ignite below 175°F (79°C). The Cleveland open cup method is used to measure the flash and fire points of all petroleum products except fuel oils and those materials which ignite below 175°F (79°C).

Economy Tester has a rheostat controlled 600 Watt electric heater. The open flash cup rests on an asbestos-insulated platform. A pivot-mounted gas test flame burner and a thermometer holder are attached.

Applicable Tests: AASHTO T48, ASTM D 92

19.NCAT IGNITION FURNACE (ASPHALT BINDER CONTENT TEST)

Asphalt binder ignition testing is an environmentally friendly and cost effective test method to determine asphalt content of paving mixtures and ensure high quality and economical asphalt product. The ignition method reduces testing time when compared to solvent extraction.. Asphalt binder ignition testing is an environmentally friendly and cost effective test method to determine asphalt content of paving mixtures and ensure high quality and economical asphalt product. The ignition method reduces testing time when compared to solvent extraction..

A 1,200-1,800g sample of asphalt can be tested in 30-45 minutes with the NCAT Furnace. The unit can accommodate samples up to 5,000g at extended testing times. The method also eliminates the cost of solvent, the secondary cost of solvent disposal and safety concerns when handling solvent in the lab. Weight change due to sample and basket assembly temperature change is automatically compensated for each sample tested. The automatically detected endpoint of the test cycle is reached when weight loss from the sample is less than a userestablished setpoint between 0.01% and 0.5% for three consecutive readings. Test results are computed as asphalt content per total weight of HMA sample or bitumen ratio per weight of dry aggregate to an accuracy of ±0.11%.

The furnace is pre-heated to a setpoint temperature within the range of 450°-650°C (842°-1,202°F). The default setting is 538°C (1,000°F). The hot-mix asphalt sample is weighed and divided into two screened baskets on a tray assembly. This complete assembly is placed in the chamber on the furnace hearth tray. Once the door is closed and the test initiated, the door remains locked until completion. During ignition and burn-out, released volatiles are further oxidized in a hightemperature afterburner with a patented ceramic filter heated to 750°C (1,382°F). This system has been shown to reduce process emissions by up to 95%.

Geotechnical Laboratory

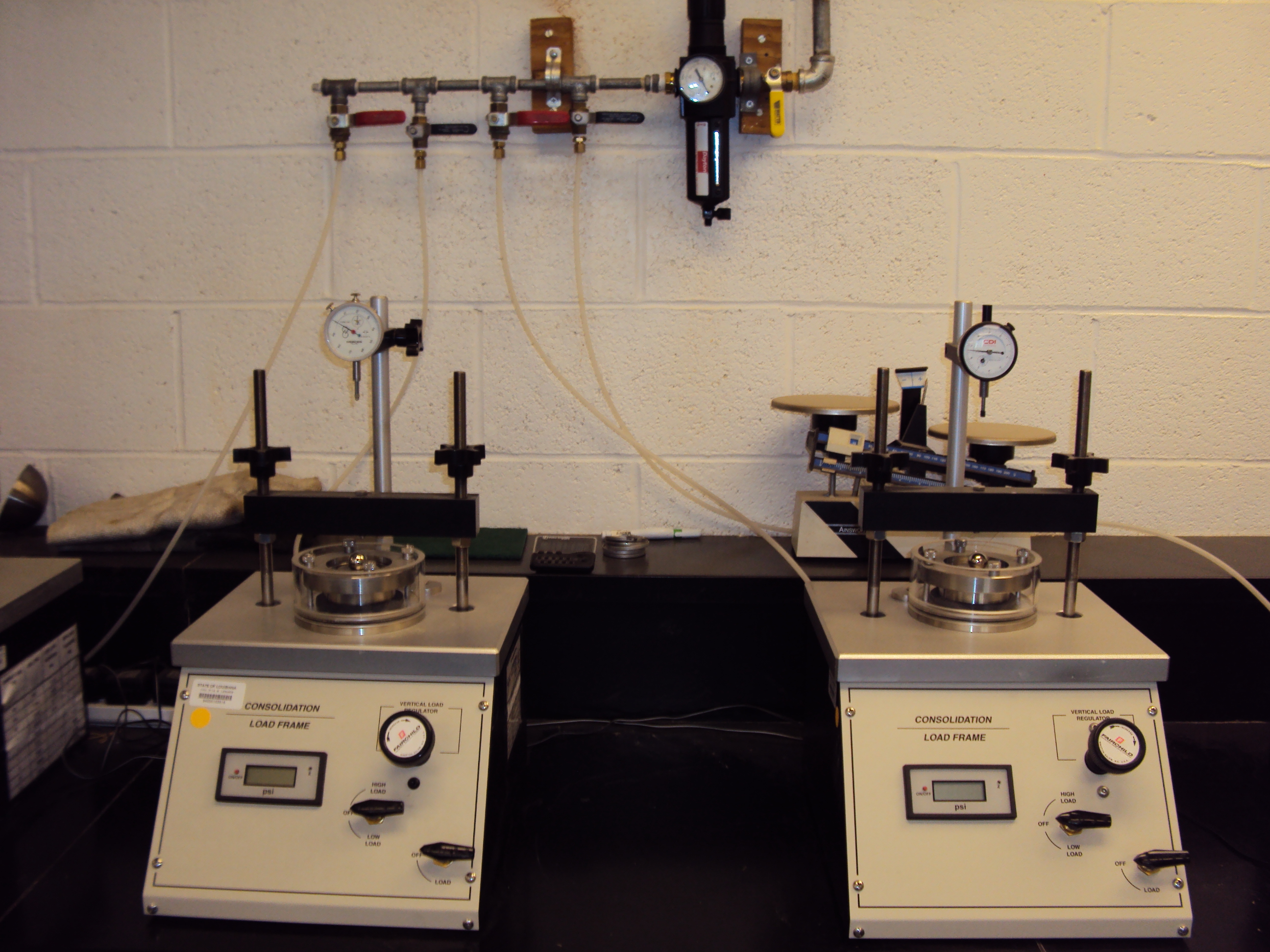

1.CONSOLIDOMETER

One-dimensional consolidation of soils provides information for calculating expected settlement for

structures and pavements. Karol-Warner Consolidation Frames meet the most stringent demands of soil testing labs.

Pneumatic Consolidation Systems are available in two different load capacities. Both instantaneously

apply and maintain pneumatic loads for precision consolidation testing for application of small loads

from 100-3,200psf (4.8-153.2kPa). All necessary weights are included. Applied loads are maintained

by a precision pressure regulator.

Fixed or floating ring consolidation cells are used with consolidation frame. The 2.5in (63.5mm)

dia. consolidation rings include a stainless steel base, load pad, ball bearing and two porous stones.

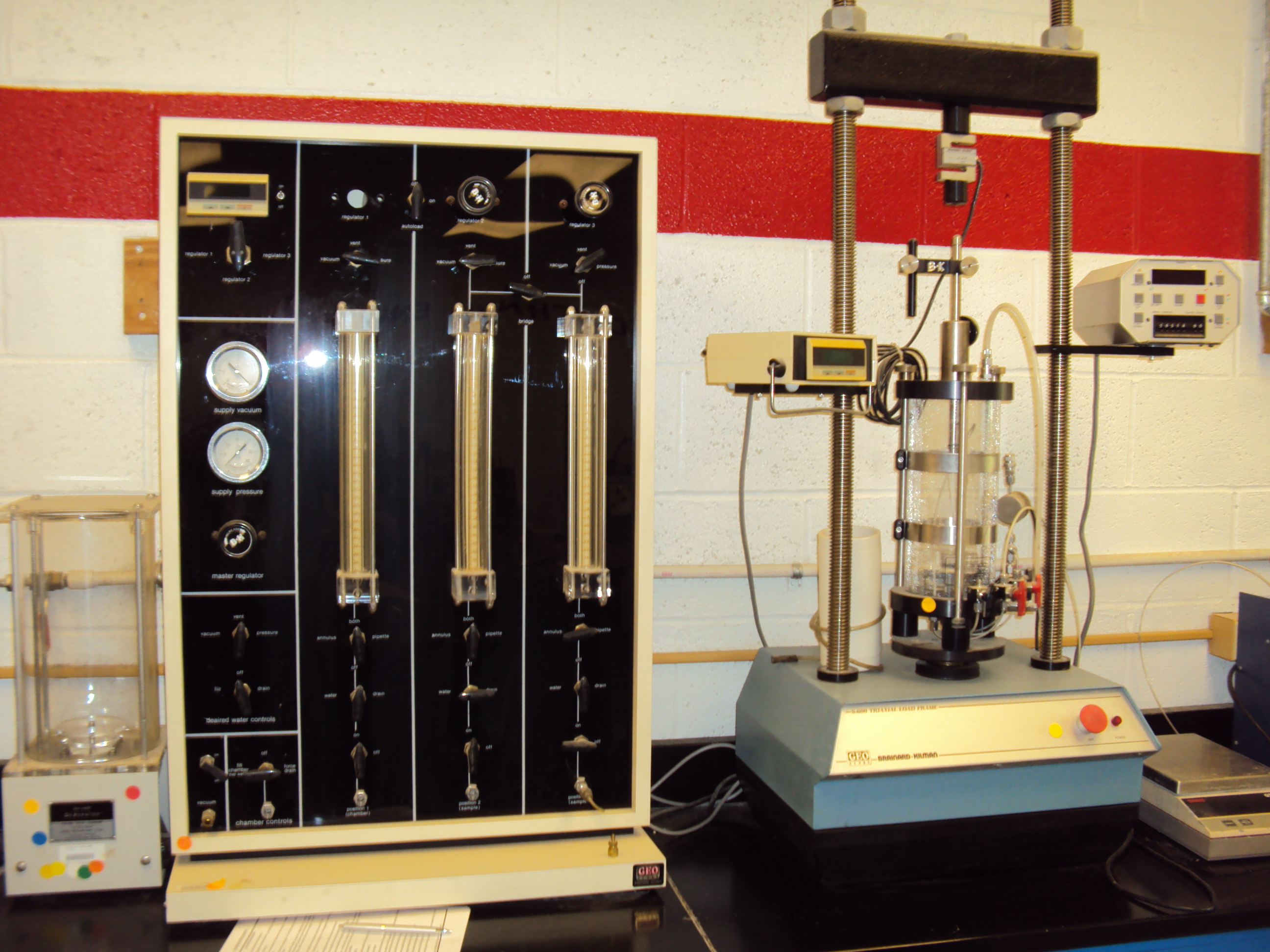

2.TRIAXIAL AND PERMEABILITY TEST APPARATUS

Master Control Panel combines precise control and ease of operation. Controls in the upper half of the panel regulate air pressure to the specimen chamber while the lower controls regulate the water supply. All cell and burette pressures are individually adjustable and easily monitored by a single digital pressure gauge. The panel includes two burettes and two pipettes for accurate permeability flow measurements. Accurate measurement of pore pressure for correction and control of loads and loading rates can be accomplished with the Pore Pressure Gauge. Master Control Panel combines precise control and ease of operation. Controls in the upper half of the panel regulate air pressure to the specimen chamber while the lower controls regulate the water supply. All cell and burette pressures are individually adjustable and easily monitored by a single digital pressure gauge. The panel includes two burettes and two pipettes for accurate permeability flow measurements. Accurate measurement of pore pressure for correction and control of loads and loading rates can be accomplished with the Pore Pressure Gauge.

Triaxial Test Chambers have precision-ground and polished stainless steel load piston Triaxial chambers can also be used for flexible wall permeability testing applications. Chamber allows triaxial testing of both soils samples up to 3-inch (152mm) diameter and 6-inch in height.

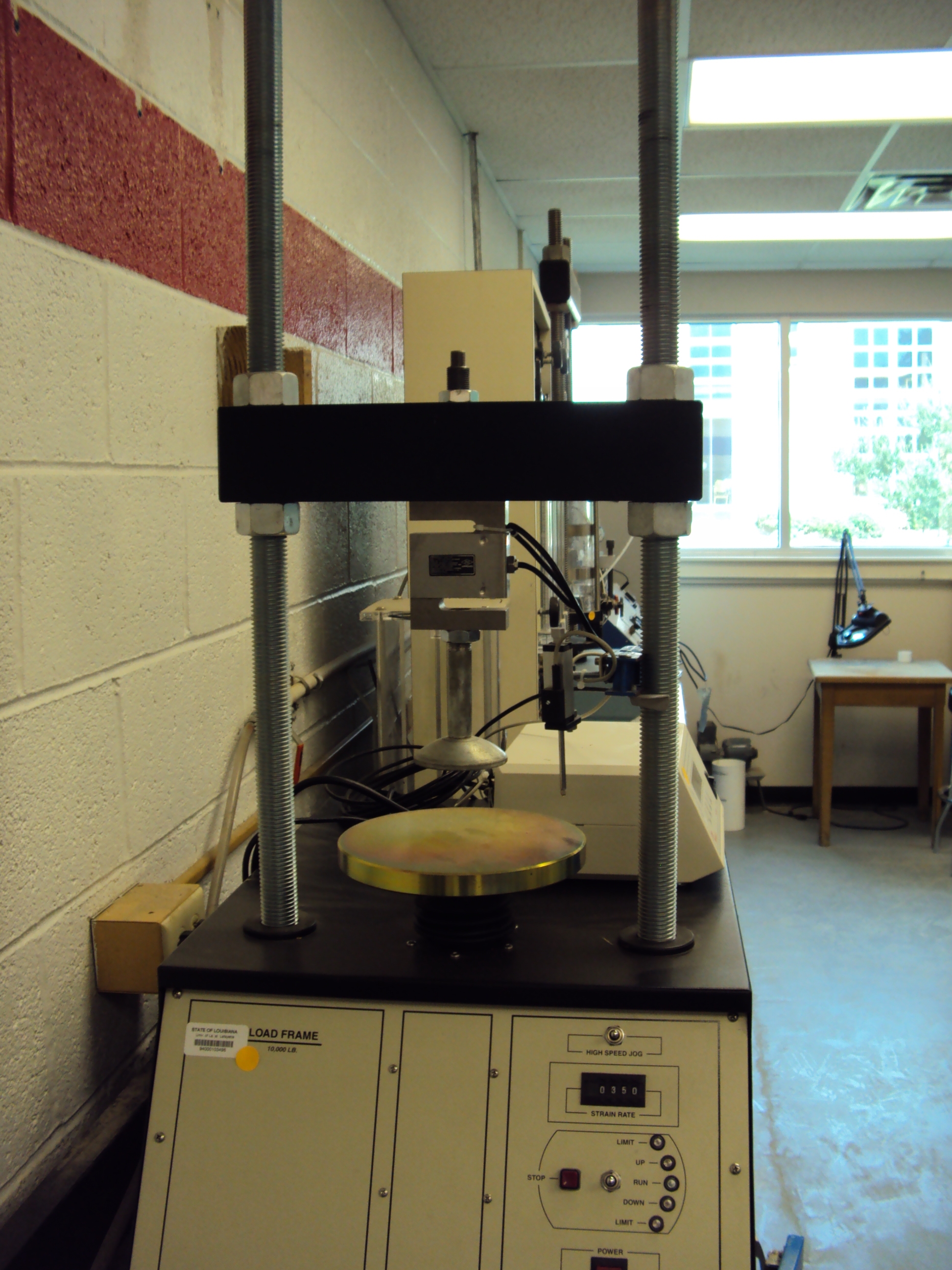

Load Frame has variable speed ranges from 0.02-2.0in (0.508-50.8mm) with capacity of 5000lbs.

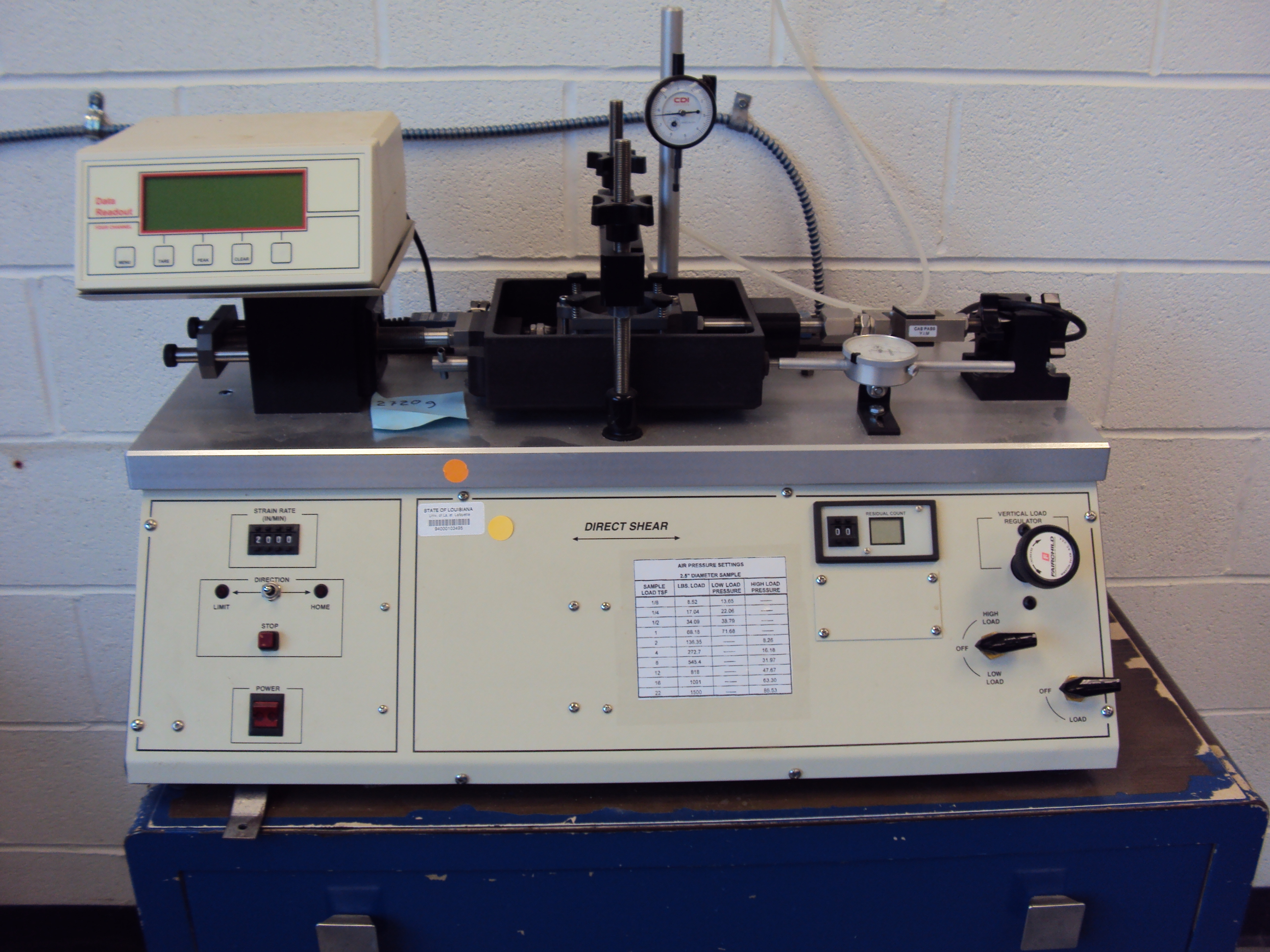

3.DIRECT SHEAR TESTER

Shear displacement tests determine direct

and residual shear of consolidated drained

and un-drained soils and give engineers

valuable information for evaluating

strength and stability of soils.

Shear displacement tests determine direct

and residual shear of consolidated drained

and un-drained soils and give engineers

valuable information for evaluating

strength and stability of soils.

Vertical loads are applied using pneumatic pistons. A small, rolling diaphragm piston accurately applies light vertical loads of 4-100lbf (0.018-0.44kN) and the large diameter piston applies loads up to 1,500lbf (6.67kN). This design increases the sensitivity and accuracy of the light load system. Loading is controlled by setting the precision regulator to the desired pressure per the included calibration chart. Load settings are displayed digitally.

4.UNCONFINED COMPRESSION TESTER

Load Frame is designed for variable speed ranges from 0.02-2.0in (0.508-50.8mm) per minute allow running Marshall, Lottman, CBR, unconfined compression, soil-cement, and basic triaxial tests, all on a single unit. The 3/4hp DC motor and controller precisely control strain rates to ±1% of set point. Strain rates or loading rates are easily selected from the push button control panel with digital displays. Travel limit switches with indicating lights protect the unit from damage due to platen travel outside of its 3 in (76mm) range.

Load Frame is designed for variable speed ranges from 0.02-2.0in (0.508-50.8mm) per minute allow running Marshall, Lottman, CBR, unconfined compression, soil-cement, and basic triaxial tests, all on a single unit. The 3/4hp DC motor and controller precisely control strain rates to ±1% of set point. Strain rates or loading rates are easily selected from the push button control panel with digital displays. Travel limit switches with indicating lights protect the unit from damage due to platen travel outside of its 3 in (76mm) range.

Applicable Test Methods

AASHTO T245

AASHTO T283

ASTM D 4867

ASTM D 5581

ASTM D 6927

5.ATTERBERG LIMIT TEST

Liquid limit is the water content at which soil changes from liquid to plastic state. It is arbitrarily defined as that point where two halves of a soil sample flow together when jarred in a specified manner using a Liquid Limit machine.

Gilson's Hand-crank operated machines with automatic impact counter, and a budget hand-crank model without counter are available in the lab. All models consist of a brass cup suspended from a carriage designed to control its drop exactly 1cm onto a hard rubber base. Height of drop is adjusted by a nut at the rear of the cup carriage using the gauge at one end of the plastic Casagrande grooving tool

Plastic limit is defined as the water content at which a soil can no longer be deformed by hand rolling to 1/8in (3.2mm) diameter threads without crumbling. Main items needed for this test are Glass Plate and Aluminum Containers. Patented Plastic Limit Roller for soils is a unique time saving device designed to produce consistent results by an easily-repeatable mechanical technique. ASTM accepted and adopted from by Texas DOT. Such device obtained from Gilson is also a part of lab.

Plastic Limit Roller device consists of top and bottom roller plates separated by 1/8in (3.2mm) side rails. Contact surfaces of the plates are covered with sheets of special adhesive-backed absorbent paper that adds no fiber to soil samples. Soil samples are rolled between the moving top plate and fixed bottom plate. Soil thread diameters are reduced by back and forth action until the top plate contacts the 1/8in (3.2mm) side rails, preventing further thread size reduction.

Shrinkage limit of cohesive soils is defined as the water content at which further loss of moisture will not cause a decrease in volume. ASTM recommends this new method as an alternative to the original D 427 test method. This procedure uses similar apparatus for preparation of a soil pat, but requires immersion of the pat in melted wax. This step prevents absorption during a subsequent immersion in water for mass determination.

Gilson's shrinkage limit set includes a special Monel shrinkage dish, a metal straightedge, fine thread to suspend the soil pat, a glass calibration plate and a tube of petroleum jelly, used when calibrating the dish. The wax melting pot is also available.

6.PROCTOR TEST EQUIPMENT

The purpose of the proctor test is to determine the proper amount of mixing water and the degree of denseness which can be expected from compaction at this optimum water. The end result is the moisture density relationship for a soil.

The purpose of the proctor test is to determine the proper amount of mixing water and the degree of denseness which can be expected from compaction at this optimum water. The end result is the moisture density relationship for a soil.

Manual soil rammers, or compaction hammers, are used to compact soil samples for moisture-density relationship (Proctor) testing. These models are all constructed from rust-resistant plated steel and have a 2in (51mm) circular face.

Standard Compaction Hammer has 5.5lb (2.5kg) mass enclosed in a guide sleeve with vent holes to insure unrestricted free-fall. Drop is 12in (305mm).

Modified Compaction Hammer has 10lb (4.5kg) mass enclosed in a guide sleeve with vent holes to insure unrestricted free-fall. Drop is 18in (457mm).

Mechanical Soil Compactor are also utilized that automatically counts the number of hammer blows and shuts off when a preset number is reached. The sample mold indexes to a new position with each count to assure uniform compaction. The Compactor can be used with the 4in (102mm) ID molds, 5.5lb (2.5kg) weight with 12in (305mm) drop. It also accomodates the 6in (152mm) ID molds using either the standard 5.5lb (2.5kg) weight with 12in (305mm) drop or the modified 10lb (4.5kg) weight with 18in (457mm) drop. The standard 2in (51mm) hammer can be replaced by one of the same 3.14in2 area, but with pie-shaped face to cover entire sample surface with 6in molds. The hammer lift compensates hammer drop for soil thickness in the mold during compaction. The free-fall hammer has weight concentrated at the foot and adjusts easily from 5.5-10lb by addition of a surcharge weight.

The ASTM soil hydrometer is graduated to read specific gravity, with a range of 0.995-1.038 in 0.001 divisions at 68°F (20°C). The ASTM 152 H measures in grams per liter (g/L) of suspension and has a range of -5-+60 g/L, in 1g/L divisions at 68°F (20°C). The 280mm long ASTM hydrometers are useful for clay, silt and fine aggregate particle size distributions and can be used with other materials where absolute density has little variation among sample particles. The Constant Temperature Bath controls temperature at 68°F (20°C) during sedimentation. Holds eight Sedimentation Cylinders, all accessible with support brackets, and provides gentle, thorough agitation and circulation. Tank has stainless steel interior parts; exterior is enameled steel. Temperature control is uniform throughout bath at ±0.5°C.

7.GRAIN SIZE DISTRIBUTION

The texture of a soil is its appearance or "feel" and it depends on the relative sizes and shapes of the particles as well as the range or distribution of those sizes. Grain size distribution of soil is obtained by conduction sieve analysis and hydrometer analysis.

Sieve Analysis requires a set of sieves stacked at the top of each other with larger opening size sieve at the top and smaller opening sieves at the bottom. Oven dry soil is shacked and weight retained in each sieve is recorded.

The Gilson's Sieve Shaker is a portable 8in (203mm) sieve shaker with1/4hp unit is widely accepted by state transportation departments for highway materials testing. Back and forth lateral motion is combined with up and down and tilting motions causing test material to travel in an orbit on the sieve surfaces. The shaker is recommended primarily for No.4 to No.200 size range, but may be used with larger material sizes when specifications for sieve loading and sample quantities permit. The Shaker holds 6 full-height sieves and pan or thirteen half-height sieves and pan. Clamp bar with attached cover secures sieves. The 15 minute timer has an adjustable knob-stop for improved repeatability, and a "hold" feature for continuous running.

Hydrometer analysis calls for periodic hydrometer readings for up to 24 hour period. A 1000ml sedimentation cylinder, or hydrometer jar, is required for each sample. For consistent results, temperature may be maintained in a constant temperature bath during this period. Cylinders are 18in (457mm) in height x 2.5in (64mm) diameter. Samples are dispersed in sodium hexametaphosphate solution prior to sedimentation using a apparatus with special mixing paddle and dispersion cup. Stirring apparatus has 13,000/16,000/18,000rpm speeds and comes in aluminum housing with 5ft (1.5m) cord.

The ASTM soil hydrometer is graduated to read specific gravity, with a range of 0.995-1.038 in 0.001 divisions at 68°F (20°C). The ASTM 152 H measures in grams per liter (g/L) of suspension and has a range of -5-+60 g/L, in 1g/L divisions at 68°F (20°C). The 280mm long ASTM hydrometers are useful for clay, silt and fine aggregate particle size distributions and can be used with other materials where absolute density has little variation among sample particles. The Constant Temperature Bath controls temperature at 68°F (20°C) during sedimentation. Holds eight Sedimentation Cylinders, all accessible with support brackets, and provides gentle, thorough agitation and circulation. Tank has stainless steel interior parts; exterior is enameled steel. Temperature control is uniform throughout bath at ±0.5°C.

8.RELATIVE DENSITY APPARATUS

Apparatus is used to determine relative density of granular soils which normally do not respond well to conventional Proctor moisture-density compaction tests. Maximum density is determined by placing soil in special molds and densifying using a vibrating table and surcharge. Minimum index density is determined by loose placement in the molds using special pouring funnels, scoop, or shovel, depending on size of soil particles.

Vibratory Table has a cushioned steel 30x30in (762x762mm) vibrating deck activated by electromagnetic vibrator with over 100lb (45.5kg) actuator. The table has 750lbs (341kg) load capacity and requires 800 Watts, 12 amps at 230V. Table height is 21in (533mm). Vibration rate is 3,600VPM (3,000 at 50Hz) and amplitude adjusts in accordance with ASTM requirements. The solid state circuitry allows precise amplitude control even with fluctuating voltage supplies.

Vibratory Table has a cushioned steel 30x30in (762x762mm) vibrating deck activated by electromagnetic vibrator with over 100lb (45.5kg) actuator. The table has 750lbs (341kg) load capacity and requires 800 Watts, 12 amps at 230V. Table height is 21in (533mm). Vibration rate is 3,600VPM (3,000 at 50Hz) and amplitude adjusts in accordance with ASTM requirements. The solid state circuitry allows precise amplitude control even with fluctuating voltage supplies.

Cylindrical Mold Sets for 0.1 and 0.5ft3 (2.83 and 14.2L) capacity have attached carrying handles and guide brackets for the Gauge Set. They come complete with detachable guide sleeve with clamp assembly, surcharge base plate with removable handle, and surcharge weight with handle. Mold is 6in (152.4mm) ID x 6.112in (155.2mm) IH; surcharge weight plus base plate has 56.5 ±0.5lb (25.5 ±0.2kg) total weight. Larger mold is 11in (279.4mm) ID x 9.092in (230.9mm) IH with 190 ±2lb (86.2 ±0.9kg) total weight of base plate with surcharge weight.

Field Density Measurements

The sand cone density test is an inexpensive method of determining in-place density of soils having maximum particle sizes up to 2in (51mm) using test hole volumes of approximately 0.1ft3 (2.8L).

Sand Cone Density Apparatus is a 1gal (3.8L) threaded plastic jar with detachable brass double cone fitting. The brass cone is threaded on one end, flanged to 6-1/2in (165mm) on the other, with a brass cylindrical valve of 1/2in (12.7mm) dia. orifice between ends. Valve has stops to prevent rotating past completely open or closed positions.

Density Plate is 12x12in (305x305mm) aluminum alloy with 1/2in (12.7mm) high edge walls to contain soil sample that is dug using 6-1/2in (165mm) center hole of plate as a guide. After test hole is prepared, flange of cone fits plate opening for filling hole with special Density Sand. Density Sand is clean, dry, uniform, uncemented, durable, and free-flowing. Few particles pass No.200 (75¼ m) or are retained on No.10 (2mm) sieves. Bulk density varies less than 1%. 50lb (22.7kg) packing bag is heavy and reinforced

Materials Testing Laboratory

1.MATERIALS TESTING SYSTEM (MTS)

The 810 Material Testing System delivers a broad array of testing capabilities for both low and high force static and dynamic testing. By selecting from a variety of force capacities, servovalve flow ratings, pump capacities, software, and accessories, the floor-standing 810 system can easily be configured to meet your specific material or component testing needs. The load capacity of MTS available in the ITML laboratory is between 20-200-kips. The MTS is also equipped with environmental chamber for low and high temperature testing.

|

|

| 20-kips Load Capacity MTS |

200-kips Load Capacity MTS |

2.IMPACT TOUGHNESS TESTER

The impact toughness of a material can be determined with a Charpy or Izod test. These tests are named after their inventors and were developed in the early 1900's before fracture mechanics theory was available. Impact properties are not directly used in fracture mechanics calculations, but the economical impact tests continue to be used as a quality control method to assess notch sensitivity and for comparing the relative toughness of engineering materials.

The impact toughness of a material can be determined with a Charpy or Izod test. These tests are named after their inventors and were developed in the early 1900's before fracture mechanics theory was available. Impact properties are not directly used in fracture mechanics calculations, but the economical impact tests continue to be used as a quality control method to assess notch sensitivity and for comparing the relative toughness of engineering materials.

3.HARDNESS TESTER

Hardness is the resistance of a material to localized deformation. The term can apply to deformation from indentation, scratching, cutting or bending. The Rockwell Hardness test uses a machine to apply a specific load and then measure the depth of the resulting impression. The indenter may either be a steel ball of some specified diameter or a spherical diamond-tipped cone of 120° angle and 0.2 mm tip radius, called a brale. A minor load of 10 kg is first applied, then, the dial is set to zero and the major load is applied. Upon removal of the major load, the depth reading is taken while the minor load is still on. The indenter and the test load used determine the hardness scale that is used (A, B, C, etc).

Hardness is the resistance of a material to localized deformation. The term can apply to deformation from indentation, scratching, cutting or bending. The Rockwell Hardness test uses a machine to apply a specific load and then measure the depth of the resulting impression. The indenter may either be a steel ball of some specified diameter or a spherical diamond-tipped cone of 120° angle and 0.2 mm tip radius, called a brale. A minor load of 10 kg is first applied, then, the dial is set to zero and the major load is applied. Upon removal of the major load, the depth reading is taken while the minor load is still on. The indenter and the test load used determine the hardness scale that is used (A, B, C, etc).

Computational Laboratory

|